3D Printing

Constructing a model or prototype using fused filament fabrication

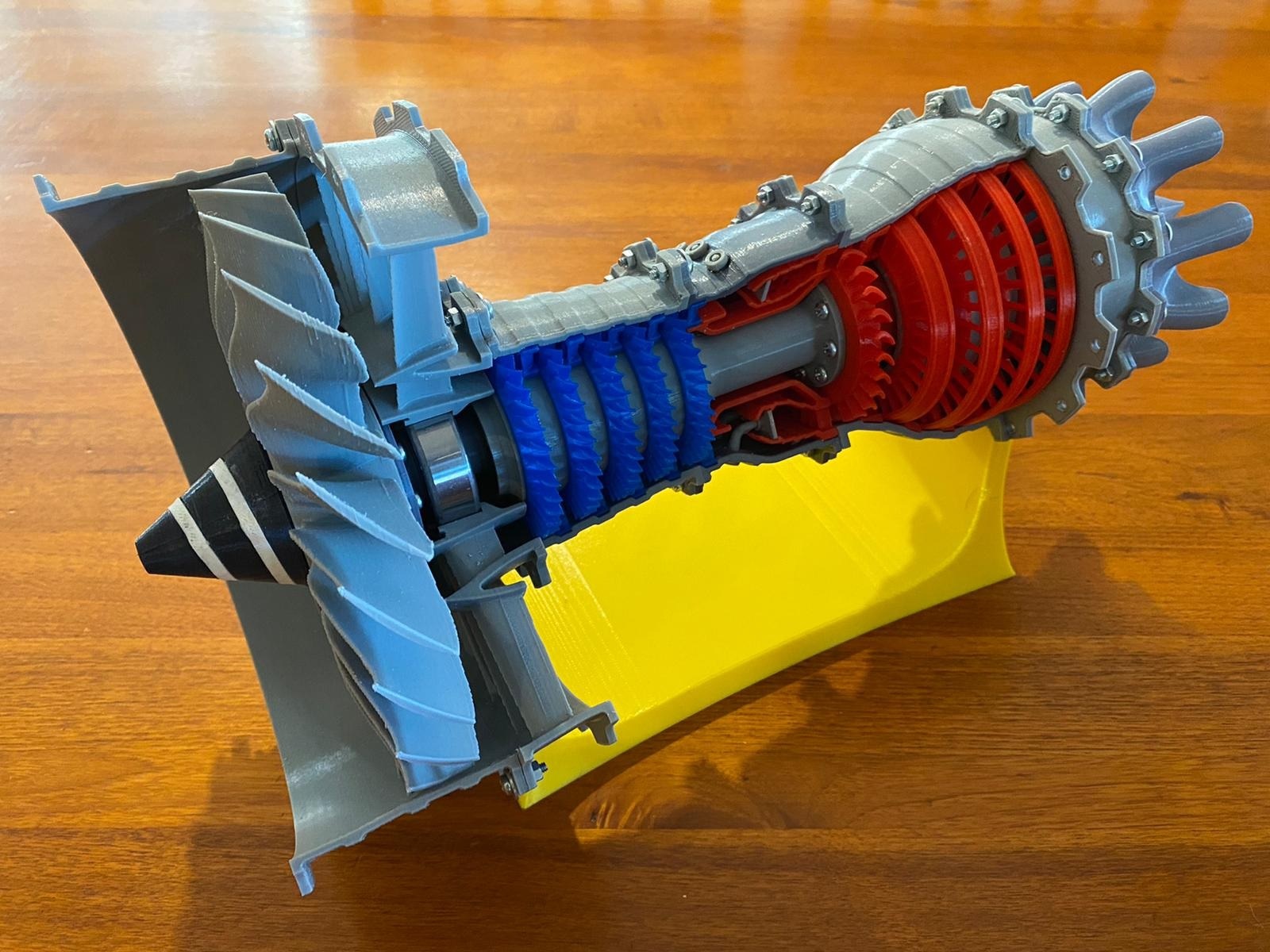

There are a variety of 3D printing processes available today. One of the simplest forms uses a technology called Fused Filament Fabrication. The process uses a plastic filament that is heated to become soft and pliable before being extruded through a heated nozzle and deposited layer by layer gradually building up a three dimensional shape. The printing process is controlled by a computer program that translates the output from CAD/CAM software into a 3D object. The Dream Team use this process to build simple models as part of the 3D modelling process to allow you to see your dream as a real model.

There are a variety of 3D printing processes available today. One of the simplest forms uses a technology called Fused Filament Fabrication. The process uses a plastic filament that is heated to become soft and pliable before being extruded through a heated nozzle and deposited layer by layer gradually building up a three dimensional shape. The printing process is controlled by a computer program that translates the output from CAD/CAM software into a 3D object. The Dream Team use this process to build simple models as part of the 3D modelling process to allow you to see your dream as a real model.

As a first step to investment casting or metal additive manufacturing we produce a plastic 3D model or prototype of the design. This allows you to physically conceptualise the design in a real world environment. It is a cost effective way to evaluate the end product in terms of it's look and feel. It also allows potential investors to get a physical taste of your dream. They say that a picture is worth a 1000 words. Well a 3D model is worth a million.

As a first step to investment casting or metal additive manufacturing we produce a plastic 3D model or prototype of the design. This allows you to physically conceptualise the design in a real world environment. It is a cost effective way to evaluate the end product in terms of it's look and feel. It also allows potential investors to get a physical taste of your dream. They say that a picture is worth a 1000 words. Well a 3D model is worth a million.